Historic tiles like clay and ceramic type pass a long process in building. Replacement resources as an important issue beside replacing flashing process is defined and explained in this paper in order to give technical information about the mentioned subject matter.

Tile Replacement Resources

For replacement resources, when restoring or repairing a roof that is covered in clay tiles, it is always recommended to save and reuse as many of the original tiles as possible.

Even if the majority of the “cover” tiles on a “pan and cover” type tile roof are broken and need to be replaced, it is often possible to reuse all or the majority of the “pan” tiles, which are less likely to be damaged than the “cover” tiles.

This is because the “pan” tiles are made of a more durable material. On the other hand, if more than thirty percent of the roofing tiles are missing, broken, or irreparably damaged, it is possible that all of the old, matching tiles will need to be replaced with new ones unless replacements that are a perfect match can be located.

When determining the quantity or percentage of missing or damaged tiles that need to be replaced, it is essential to order additional tiles in order to account for breakage and damage that may occur not only during shipping but also on the actual construction site.

It is important to take note of the tile size, including whether it is graduated across horizontal rows, as is common, for example, on conical or tower roofs, or whether it is uniform across the board and laid with varying degrees of exposure to account for changes in perspective.

It is important to take note of the tile size, including whether it is uniform across the board and laid with varying degrees of exposure to account for changes in perspective.

Numerous tiles that date from the late 19th and early 20th centuries have markings on the back that list the name of the manufacturer, the size, and the name of the specific tile shape. These markings can be found on numerous tiles.

Many of the traditional tile shapes are still manufactured by some of the same companies that were active in the United States at the turn of the century; consequently, it is possible that these companies will be able to supply the necessary replacements.

However, it is essential to be aware that there are occasions in which, despite the fact that the name of a particular tile pattern has remained the same, the actual shape, size, thickness, and profile of the tile may have changed slightly.

This renders it impossible for the new tile to match the old tile sufficiently well enough to serve as an appropriate replacement for tiles that have been lost or broken. It is acceptable to use these tiles on a secondary or less noticeable elevation, or when a tile roof needs to be replaced entirely; however, it is not acceptable to use them on a portion of the roof that is very visible.

Even if a company is no longer making a particular type of tile, the company may still have the original molds for making tiles, and these molds can be used to make new tiles that are an exact match for vintage tiles if the quantity required is high enough to justify placing a custom order.

The number and company imprint on the backs of other businesses’ old tiles allow them to be matched and identified using this method. These businesses also keep a variety of old tiles in stock.

These establishments additionally stock and sell reclaimed tile. Still other companies concentrate solely on the production of one-of-a-kind replicas of vintage clay tiles in order to contribute to a particular preservation effort.

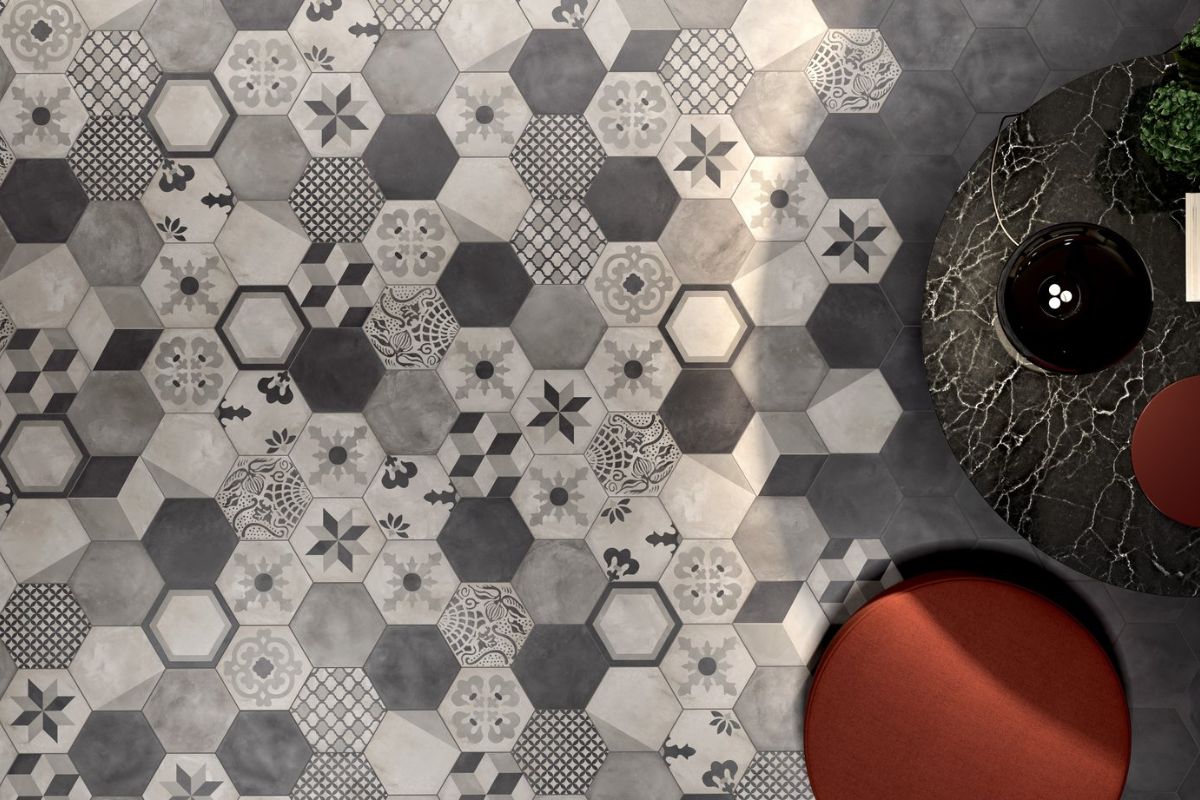

Clay tiles made today come in an even wider variety of styles and colors than those made in the past. There is a wide variety of choice available regarding sizes, shapes, and glazes.

A large number of producers provide one-of-a-kind color-blended tiles as well as tiles in a variety of colors that are designed to be meticulously matched together when they are installed.

However, it is essential to keep in mind that many of these modern tiles may not be appropriate for use on roofs that were originally constructed with clay tiles. In addition to that, the location of the production process needs to be taken into consideration.

Tiles, for example, that are intended for use in a climate that is hot and dry may not be able to withstand rain, temperature variations that are really extreme, or cycles of freezing and thawing.

Because many of the colors and tile shapes are wholly modern in design, particularly the ones that are brilliant and highly glazed, they cannot be used on historic structures because they do not correlate to traditional American styles. This renders them inappropriate for use on historic buildings.

Clay roofing tiles, as was indicated earlier, typically outlive the attaching devices used to install them. Even copper nails that have been incorrectly driven into the structural parts of the roof have the potential to become loose and fall out.

Wooden pegs deteriorate, while nails, including copper nails, corrode. Even though it is uncommon to need to replace all of the clay tiles on a roof at once unless matching replacements cannot be found, old tile roofs are frequently stripped of all of their tiles in order to relay the tiles with new fastenings and battens. This is done in order to preserve the integrity of the roof.

When the system for attaching the roof tiles fails, all of the tiles need to be removed and then reattached using new fasteners that are resistant to corrosion. If it is at all possible, each tile ought to be numbered, and a diagram ought to be drawn indicating where each tile is situated, so that it is simpler to recreate the initial pattern and color variations when the tiles are rearranged.

This will make it possible to do so more quickly. It is a good idea to assign a number to each tile in order to make certain that they are all returned to their correct locations.

In certain situations, it may be sufficient to simply group the tiles as they are removed by type, size, or purpose, such as field tiles, custom tiles for hips, dormers, and ridges, and specially cut pieces. This can be done while the tiles are being removed. However, there is no guarantee that this will ever be either practical or feasible. The tiling process will be simplified as a result of this change.

If it is necessary to remove all of the tiles, you should give some thought to installing a layer of modern roofing felt over the wood sheathing. This is because it is likely to be a good idea. This will provide a temporary sense of security and an additional layer of waterproofing while the roof is being renovated.

Even though the tiles were originally held in place by wooden pegs, it is recommended that they be rehung using hooks or nails that are resistant to corrosion; preferably, these should be made of a substantial copper or aluminum alloy.

Clay tile roofs can be secured with a wide variety of non-standard fastening mechanisms, many of which now have patents associated with them. It’s possible that certain systems are better suited than others to match a certain roof shape, or to fulfill certain requirements regarding climate or seismic activity. There is a possibility that roofing contractors and architects each have their own unique tastes.

In order to achieve the same aesthetic as the original, any battens or other roofing components of the original structure that may have deteriorated should be replaced with pressure-treated wood. It is possible that additional support will be required, particularly in the event that the original roof was either inadequate or constructed incorrectly.

Tiles Replacing the Flashing

Flashing, gutters, and downspouts that have been damaged should typically pass replacing with the new components made from the same material for tiles.

Depending on the structure, copper, lead-coated copper, or terne-coated stainless steel are often the materials of choice for use as roofing materials on historic clay tile roofs.

These materials are durable and have a long lifespan. On the other hand, copper staining from downspouts can occasionally be a problem on light-colored masonry walls, which is something to keep in mind when considering replacements for rainwater removal systems.

Clay tile roofs normally feature an open valley system, and there is metal flashing that separates the tiles at the intersections of the variously-angled roof portions.

The process of installing new flashing is much simplified as a direct result of the fact that just a few tiles in the immediate vicinity need to be removed. By brush-coating it with boiled linseed oil or other special solutions, new copper flashing that is too “bright” can be “mellowed” and made to blend in with its surroundings.

The repair that should be avoided at all costs is replacing broken or missing roof tiles on a historic building with natural clay tiles that do not correspond to the original tiles. Roofing tiles made of clay are almost never interchangeable with those made of concrete, metal, or plastic.

They do not have the same texture, form, thickness, or surface irregularities as clay tile, nor do they have the same natural color changes. Additionally, they do not have the same natural color variations.

Despite the fact that a lot of concrete and composition tiles are created to mimic the overall profile, if not the specific shape, of clay roofing tiles, concrete tiles are typically too thick and lack the diversity of colors found in natural clay tiles. Concrete tiles cannot be used to repair or replace individual, aged clay tiles in any way, nor can they be used to do so.

Patching a historic clay tile roof with roofing tar, caulk, asphalt, metal pieces, or clay tiles that don’t match the rest of the roof is not recommended. These artistic approaches cannot coexist with one another.

In addition to this, they are capable of causing people to suffer physical injury. During a cycle of freezing and thawing, localized accumulations of ice can cause neighboring tiles to fracture due to the ice’s expansion and contraction as the temperature fluctuates. The collection of water behind these spots can speed up the deterioration of the roof sheathing and the mechanisms used to secure it.

A long-term reliable business relationship is at hand if you contact us. A professional supplier and exporting team support us to have a win-win relationship with our customers.

Your comment submitted.